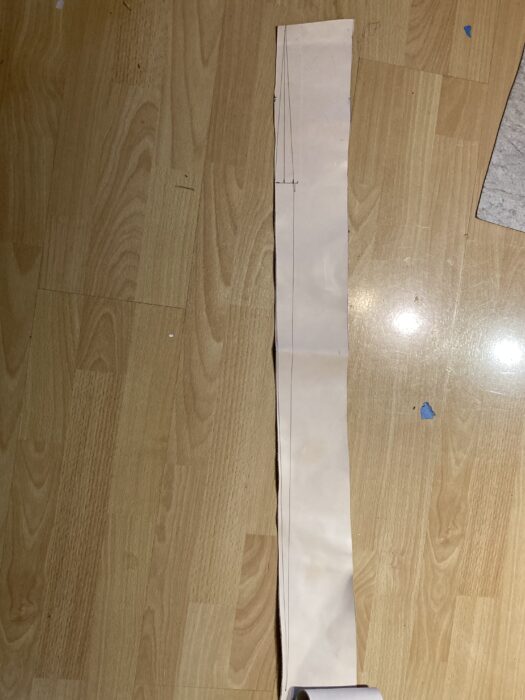

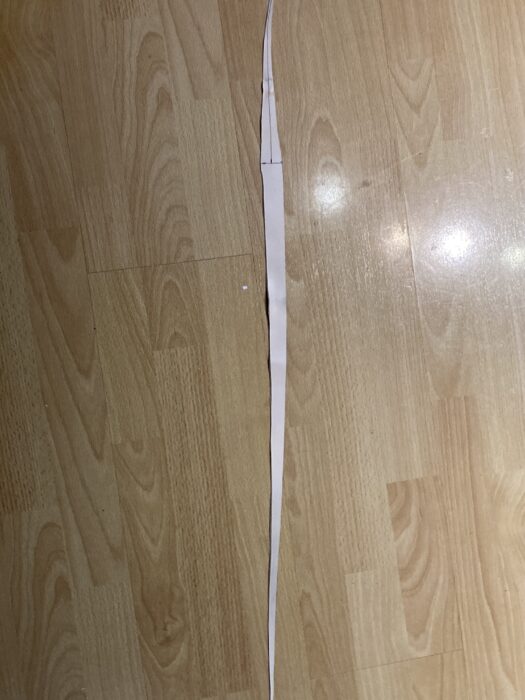

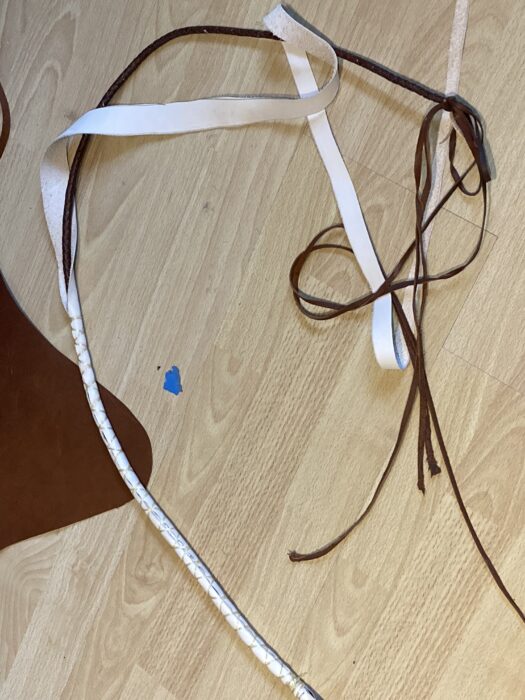

This was a fun whip repair that came in! This stock whip’s leather keeper had broken and it’s owner did a quick self repair by tying a knot to make it semi functional.

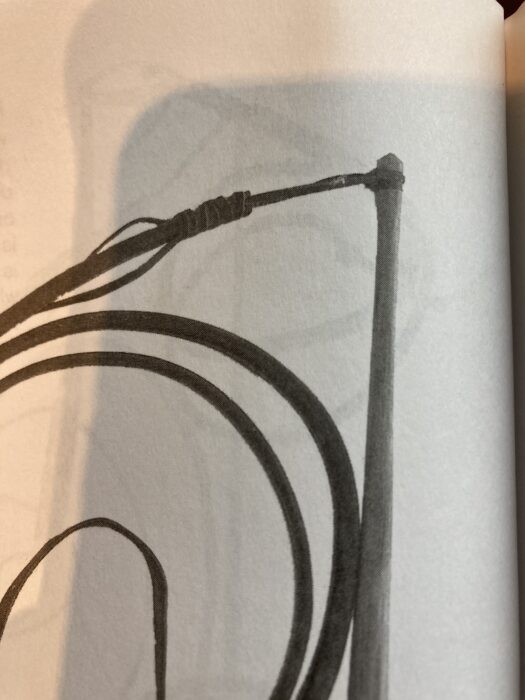

When I was contacted, I asked if they had a picture of it before it was broken so that I could try to match what it previously had, and unfortunately they didn’t. I did a little bit of research and found some samples of what I thought it might have looked like before and this is one the owner thought looked the closest.

The picture above is from Whips and Whipmaking by David Morgan. It’s an amazing resource, and if you don’t have it, you should get it!

I replaced the leather for the keeper and retied everything.

Also while I was working on it, I removed the knot that was in the fall and gave it a hit of Pecard Leather Dressing. This whip should have many more years of cracking in it!

-Louie